HIGH VACUUM PRODUCTS

UHV VACUUM SYSTEMS

Our ultra-high vacuum systems are manufactured with high purity materials, the strictest quality control standards, and superior vacuum performance to 10 -11 Torr range. While we can create systems for any application, a few systems we commonly custom manufacture for our diverse customer base include:

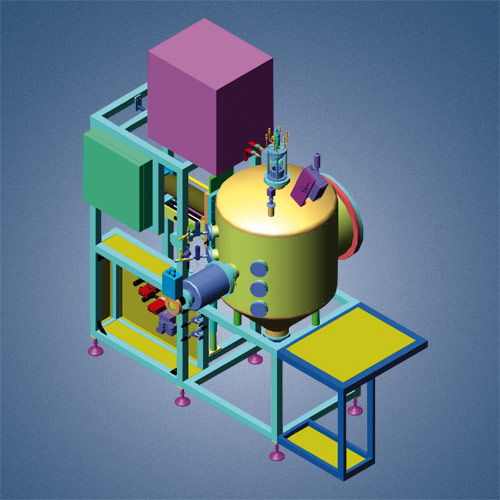

The RF/DC-ICP torch is mounted on top of the chamber. The plasma is generated from a gas mixture is comprised of 4 gasses that sprays around a cathode and through an anode. An arc ignites the plasma.

Deposition material can be introduced into the plasma jet as powder or liquid. When the liquid is used nanostructured coatings or deposits are formed with a wide variety of material compositions.

Substrate manipulation includes 6-axis of motion, high-speed substrate rotation and heating to 600° C.

A four gas distribution system consists of mass flow controllers, 20 slm range, MFC power supply/LCD display, inlet and purge valves and stainless steel gas manifold.

The chamber is pumped by a combination of a dry screw vacuum pump and a rotary booster pump complete with water-cooled foreline trap, air filter, throttling valve. Vacuum measurement is comprised of a capacitance manometer and Pirani/Piezo Transducer.

A PLC/PC based vacuum process automation system controls the pump-down and plasma deposition process. The system is user friendly with safety and process interlocks as required.

Detailed specifications and technical data is available on request. The system is modular in design and can be adapted to suit exact customer requirements in their laboratory or innovative research and design facility.

The unit also features:

- Automated pumping and venting

- Mimic panel displaying system status

- Atmosphere to UHV in 30 minutes

- A motorized multi-sample carousel

- Slide out bottom flange for easy maintenance

- ± 0.25% uniformity over 3 inch diameter samples

- Compact self-enclosed frame

The system is installed on a support table with a 19″ electrical rack and power distribution panel.

The mounted unit also includes blank-off flanges, two viewports with shutters and a high purity optical sapphire viewport. The vacuum is tested to 2×10-10 Torr with baking to 100° C. Our JUV laser deposition systems are very popular across various industry verticals because of their practicality and versatility in this very specialized area.

The vacuum chamber is an all-metal UHV chamber (18″ O.D. x 18″ high) with wire seal top and bottom flanges. It is equipped with hydraulic lift mechanisms, sample stage port, pumping port and various 2.75″, 4.5″ and 8″ Conflat ports, plus blanks. It also includes a removable liner and shuttered 4″ I.D. viewport.

In the center of the bottom wire seal flange is a 10″ O.D. Conflat flange unit with three, 2″ O.D. RF magnetrons, three electro-pneumatic shutters, a gas inlet port and a water-cooled cross-contamination shield. The guns are capable of approximately 100 A/min Fe at 4 – 5″ target substrate spacing with uniformity of ± 2% over the target diameter.