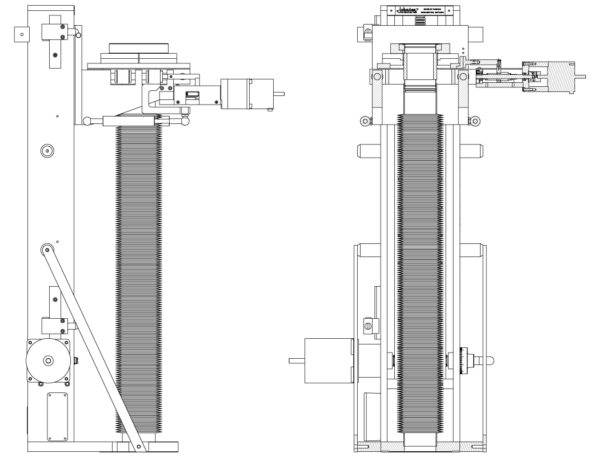

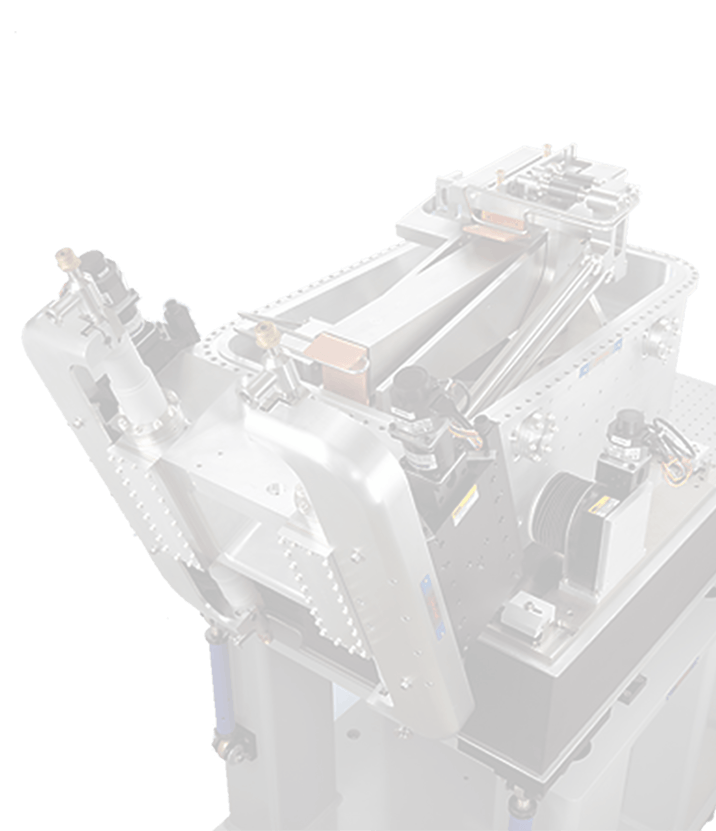

MANIPULATORS

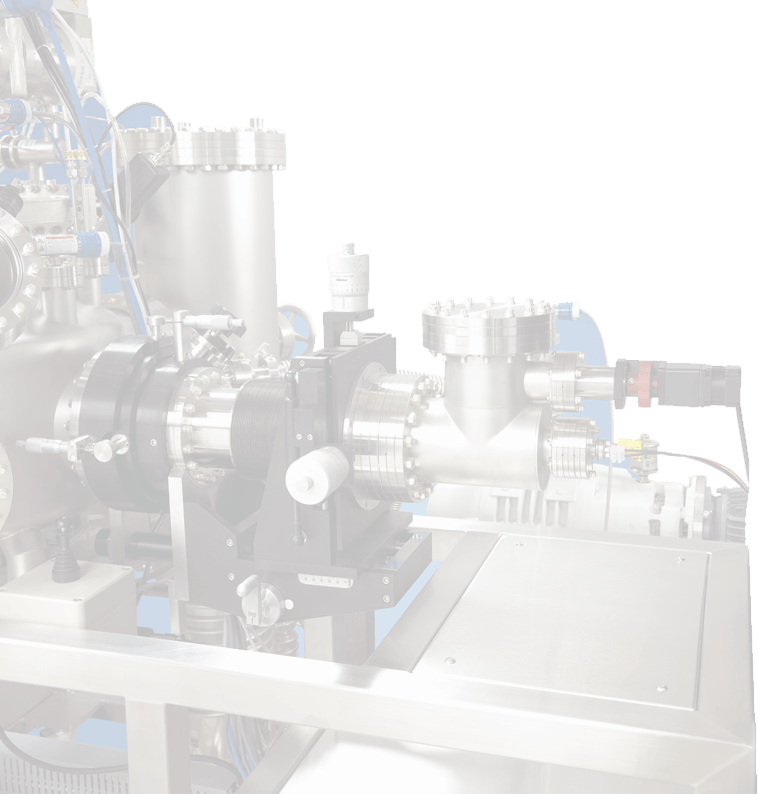

Our JUV Manipulators are well-known and inspire confidence among our customer base who use a combination of manual and motorized versions of ultra-high vacuum manipulators to position samples exactly where they require them.

We engineer and precisely manufacture versions with sample bias, heating and cooling options across the X, Y, and Z axis of travel with a R1, R2, and/or R3 rotation possibility. These can be either a manual or a mechanized motor-positioned computer-controlled manipulator – while providing unparalleled accuracy and precision. Our custom manipulators are over-engineered and allow for virtually any axis and rotation combination. We can assist with the design and development of your manipulators which will facilitate the needs of your project. Trust the 60 years of JUV to your ultra-high vacuum needs!