AEROSPACE SYSTEMS

JUV has been involved with providing some of the guidance used in the Aerospace industry based on our 60-year experience in the world of Ultra-High Vacuum technology.

We recognize the challenges that space provides (temperature extremes, pressure differentials etc.) and that having access to realistic simulation and testing facilities will help shape the future of exploration, communication, and innovation.

Johnsen Ultravac is also providing similar testing and simulation technology for evaluating and assessing the materials, components and innovations in flight on a large scale and in the experimental smaller scale aerospace applications planned for the near future. We are proud to participate as a transformational agent and contributed to the progress of our community and our culture through the use of high and ultra-high vacuum technology experiences. Some of our most popular aerospace applications include our Benchcooler and our Black Body System.

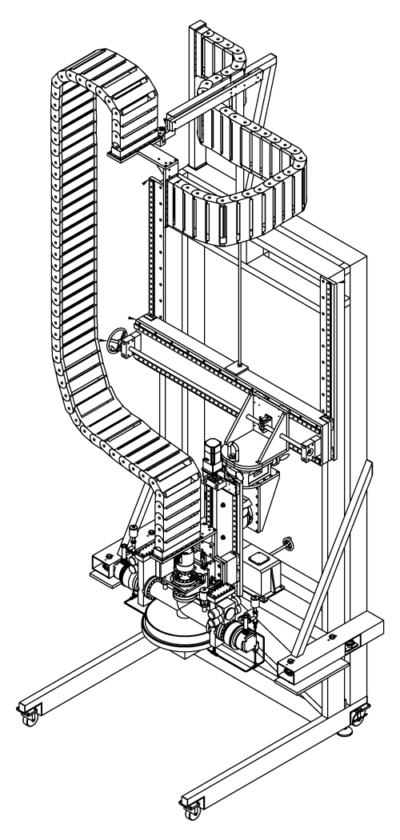

The benchcooler is a UHV system used for testing satellite components and sensors including IR in simulated space environments where extreme pressures and temperatures (below 90°K) are necessary. The JUV benchcooler is suitable for a class 100,000 clean-room environment. This is designed to operate non-stop and is completely remotely controlled with a PC/PCL connection. Our innovative engineering allows for the mounting of this system on an optical table and the two turbo molecular pumps are backed by an oil-free scroll pump which are mounted to the vacuum chamber at opposite ends. Our UHV gate valves isolate the chamber in the unlikely event of a power failure and our redundant system has the ability to maintain UHV pressure should the primary pump lose operability prematurely. There is a closed cycle two stage cryostat mounted at the top of the chamber allowing for non-contact cooling of the satellite components. Our helium compressor is cooled by two closed loop chillers and each are supported by a 50 gallon water resevoir.

Our benchcooler design allows for a proprietary cable management and custom mounting arrangements that permit 6 axis motion while maintaining the integrity of the alignment, parallelism and cooling performance while being able to accommodate various satellite component shapes and sizes. We typically utilize a residual gas analyzer (1-100amu), multi gauge control displays for vacuum pressure, temperature, sensors for vacuum status, data-logging and acquisition, and document generation and publishing.

Our Black Body System can be used as a fixed cold target at 80°K or as a variable target ranging from 180°K – 360°K with the possibility to control temperature at +/- 0.1°K intervals based on stable and accurate temperature sensors. Typical guaranteed active area is 16” square with custom sizing available for your specific requirements.